Why treat your fuel tanks on-site?

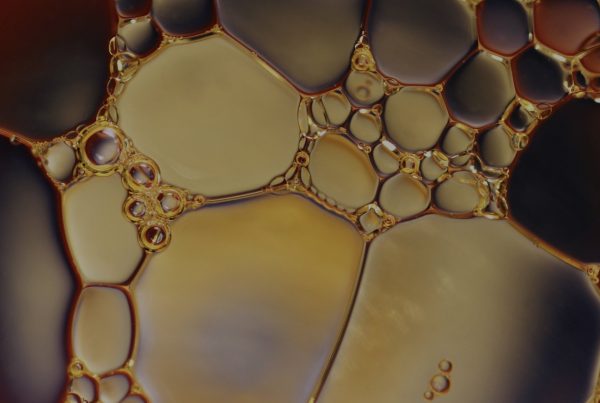

In strategic sectors such as industry, maritime, agriculture, construction, logistics, and data centers, energy reliability is a matter of survival. Stored fuels (diesel, NRD, heating oil, biofuels) are subject to natural and accelerated degradation: condensation water formation, bacterial growth, sludge and solid deposits, and internal tank corrosion.

These invisible phenomena directly compromise your operations:

- Fuel degradation: water, sludge, bacteria, and deposits affect quality.

- Unexpected breakdowns: clogged filters, damaged injectors.

- Increased maintenance costs: emergency interventions and downtime.

- Environmental impact: polluting emissions and corrosion.

- Operational risks: critical shutdowns in agriculture, industry, or data centers.

How does on-site treatment work?

Actioil provides a turnkey service that eliminates logistical constraints for your teams. Unlike traditional solutions (additives in cans, costly tank draining), our technicians intervene directly on your facilities to sanitize the fuel and protect your tanks.

- Initial diagnostic: analysis of fuel quality and tank condition.

- Injection and mixing: neutralization of water and deposits.

- Mobile filtration: advanced purification and reinjection.

- Long-lasting protection: anti-corrosion film and stabilized fuel.

⏱ Actioil guarantees intervention within 48 to 72 hours in mainland France. A decisive advantage for operators requiring continuous reliability.

What are the benefits for your business?

On-site treatment is more than just cleaning. It creates value at several levels:

- Guaranteed energy continuity: your generators and backup systems start instantly, even after months of storage.

- Cost reduction: fewer breakdowns, extended service life of filters, injectors, and tanks.

- Enhanced performance: cleaner combustion, optimized consumption, maintained engine power.

- Environmental commitment (CSR): fewer logistics-related wastes, less packaging and additives, reduced emissions.

- Versatility: a solution suitable for vessels, construction sites, transport fleets, farms, critical infrastructures, or fuel depots.

What is the cost of an intervention?

The cost depends on several factors:

- Stored fuel volume.

- Fuel type (diesel, NRD, biofuels).

- Tank condition and contamination level.

- Method selected (simple mixing or mobile filtration).

Why choose Actioil?

- Recognized expertise: decades of experience.

- A national network: interventions within 48–72h.

- Tailored solutions: adapted to your needs.

- CSR approach: sustainable and responsible innovation.

FAQ

Q: Do I need to stop my activity?

A: No, our processes are designed to adapt without interruption.

Q: Which fuels are covered?

A: Diesel, NRD, heating oil, biofuels.

Q: Is the fuel immediately usable?

A: Yes, once treated, the fuel is ready to use.

Q: Do you operate internationally?

A: Yes, upon request.

Glossary

- NRD: Non-Road Diesel, used in agriculture and construction.

- Mobile filtration: Actioil’s advanced purification process with buffer tank.

- Corrosion: tank degradation due to oxidation and water presence.

- Stabilization: process that maintains fuel quality over time.

- CSR: Corporate Social Responsibility.

With Actioil, on-site fuel tank treatment becomes a strategic investment: you secure your supply, enhance your performance, and meet your environmental commitments. Contact us for a personalized quote.